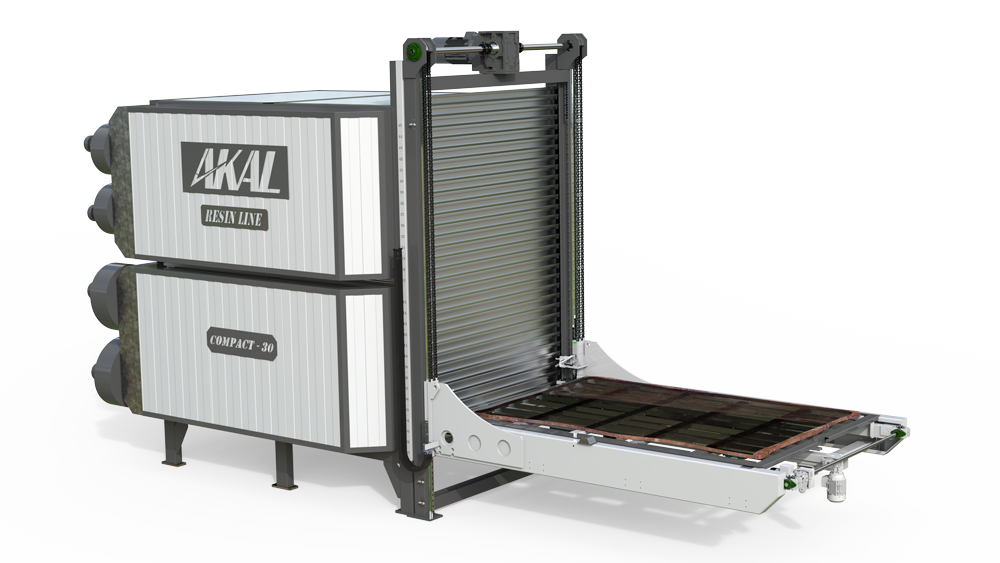

Our COMPACT model offers innovative solutions for slab epoxy repair. It achieves the same epoxy quality as large epoxy lines but in much smaller spaces.

Produced with capacities of 20, 30, and 40 slabs.

Production capacity between 10–15 and 20 slabs/hour.

Separate temperature control for drying and curing.

The slabs are transported on trays. The loaded slab is first moved to the drying section, where epoxy is applied via elevator, then transferred with the tray to the curing section. After curing, the slab is lowered and removed from the tray.

| COMPACT SERIES | 20 | 30 | 40 |

|---|---|---|---|

| Max. Production (Single Face) | 10 slabs/hour | 15 slabs/hour | 20 slabs/hour |

| Drying Capacity | 10 | 15 | 20 |

| Hardening Capacity | 10 | 15 | 20 |

| Drying Time | 60 min | 60 min | 60 min |

| Hardening Time | 60 min | 60 min | 60 min |

| Max. Slab Dimension | 3350 x 2200 x 40 mm | 3350 x 2200 x 40 mm | 3350 x 2200 x 40 mm |

| Total Electric Power | 80 kW | 100 kW | 100 kW |

| Average Power Consumption | 50 kW/h | 65 kW/h | 65 kW/h |

(Optional) Max. Slab Dimension: 3600 x 2200 x 40 mm