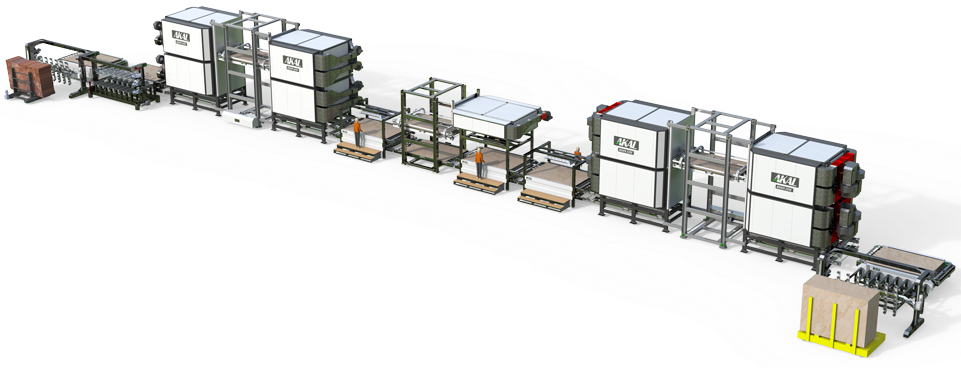

Depending on the model, these are slab epoxy systems with 30 or 40-layer drying ovens and 45, 60, or 80-layer hardening ovens.

Two-tower lines are suitable for high-capacity production in single-face epoxy operations. If double-face production is required, capacity drops by almost 50%.

| DOUBLE SERIES | 30/45 | 30/60 | 40/60 | 40/80 |

|---|---|---|---|---|

| Max. production (Single Face) | 30 slabs/hour | 30 slabs/hour | 40 slabs/hour | 40 slabs/hour |

| Drying capacity | 30 | 30 | 40 | 40 |

| Hardening capacity | 45 | 60 | 60 | 80 |

| Time of drying | 60 min | 60 min | 60 min | 60 min |

| Time of hardening | 90 min | 120 min | 90 min | 120 min |

| Max. slab dimension | 3350 x 2200 x 40 mm | 3350 x 2200 x 40 mm | 3350 x 2200 x 40 mm | 3350 x 2200 x 40 mm |

| Max. slab weight | 1000 kg | 1000 kg | 1000 kg | 1000 kg |

| Total electric power | 200 kW | 240 kW | 280 kW | 320 kW |

| Average power consumption | 70 kW/h | 90 kW/h | 120 kW/h | 150 kW/h |

(Optional) Max. Slab Dimension: 3600 x 2200 x 40 mm